Service and Maintenance

Digital Transformation Partners for Service and Maintenance

Streamline your customer service delivery, optimise your scheduling and increase the number of jobs completed per day, without recruiting more people with our Enterprise Cloud-Based Service and Maintenance Management System.

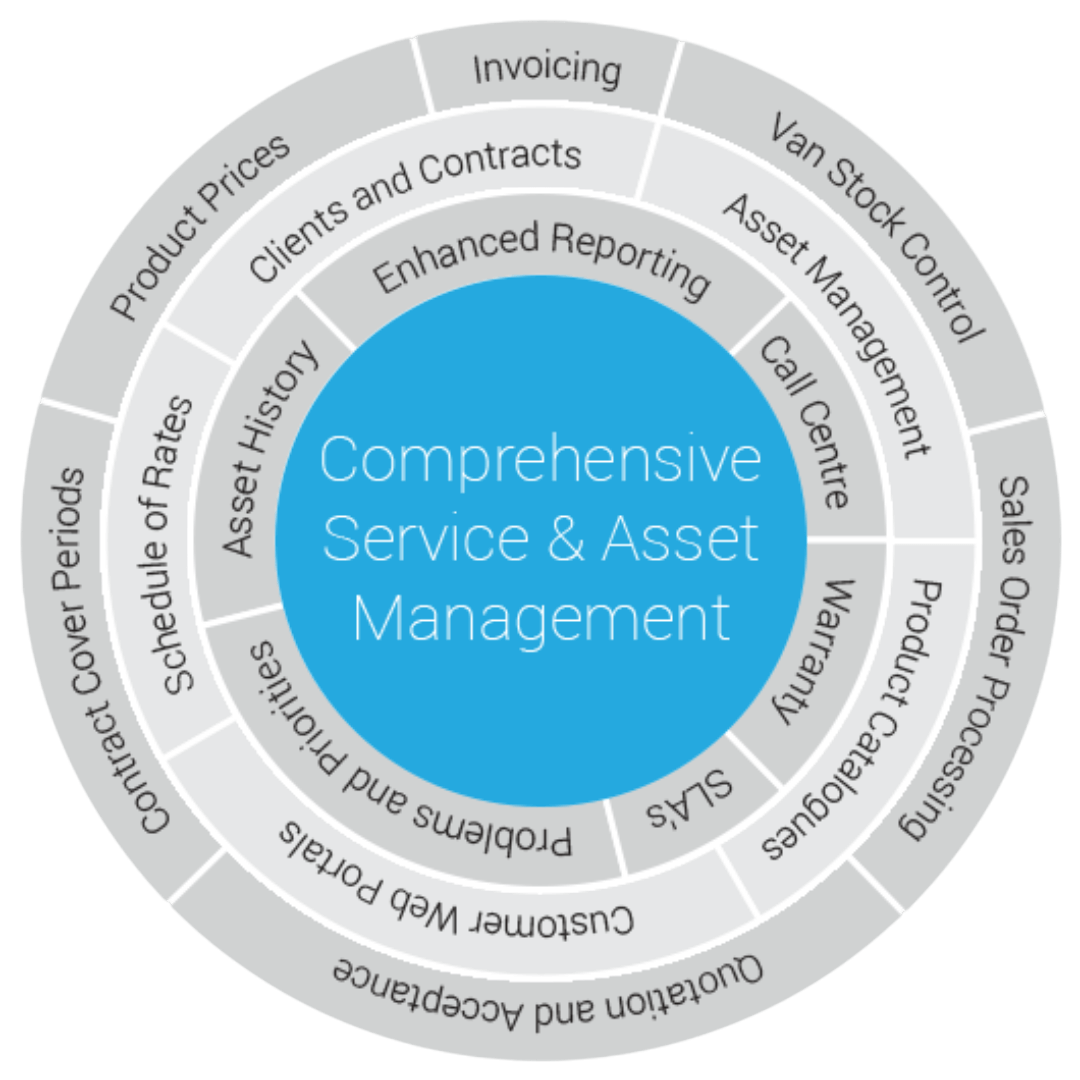

End-to-end visibility

A single view of assets, servicing, contracts, warranties, inventory, price books, costs, labour rates, margin and invoicing.

Intelligent automation

Seamless workflows, eliminate manual tasks, increasing the productivity of your service operation from day one.

Dramatic cost reduction

Strip out unproductive workforce hours with back office automation, while reducing supplier, parts, energy consumption, and maintenance costs.

The smart way to manage your assets

- Real-time visibility of assets throughout their lifecycle including asset service history, location and performance

- Increase asset uptime with intelligent planned preventative maintenance workflows

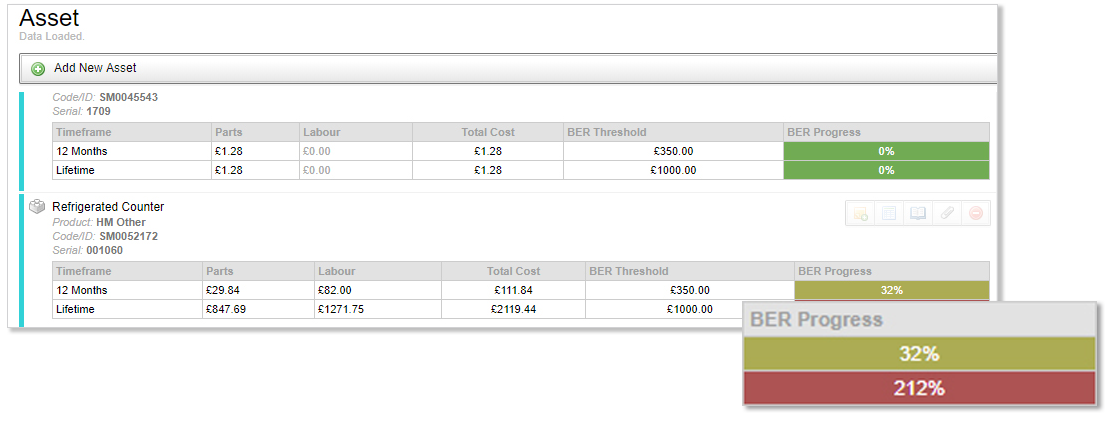

- Complete audit trail of maintenance and repair costs including Beyond Economic Repair (BER) or End of Life (EOL) status

- Eliminate costs and manual processes with seamless automated workflows for scheduling, bill of materials, quotations, parts and invoicing

- IoT monitoring of assets for planning predictive maintenance

- Maintain a complete record of contracts and warranties, logged against every asset in the database

Asset lifecycle management

- Automates the management of planned and preventative maintenance

- Track ongoing maintenance and repair

- Advanced contract, SLA and warranty monitoring

- Schedule of rates and price books

- Site and asset history

- QR code self-cleaning database

- Eliminates all service-related paperwork

- Complete lifecycle visibility of maintenance and repair costs including the tracking of Beyond Economic Repair (BER) or End of Life (EOL) equipment, allowing key decisions to be made about capital replacement

%20(1200%20x%20900%20px).png?width=1200&height=900&name=Untitled%20(1200%20x%201200%20px)%20(1200%20x%20900%20px).png)

A structured audit trail of every asset

Every asset can be given a unique asset tag to track every visit, fault and PPM service. This builds a full history including works carried out, age, warranty monitor, and costs logged against the item. This facilitates stricter cost controls, reduction in breakdowns and bespoke reporting.

Dynamic and live management of your assets allows you to build up a service history from day one. Every task, from installation to planned preventative maintenance, reactive repair or replacement, has end-to-end visibility within the system driving both performance and behaviours.

%20(1).jpg?width=2560&height=1709&name=Greggs%20Mall%20Shopfront%20(1)%20(1).jpg)

CUSTOMER STORY

How Greggs increased its shop maintenance productivity by 146%

Greggs' National Maintenance Operations Manager explains how Greggs, one of UK’s leading food-on-the-go retailers, has created a state-of-the-art, technology-led, Shop Maintenance service, with stunning results.

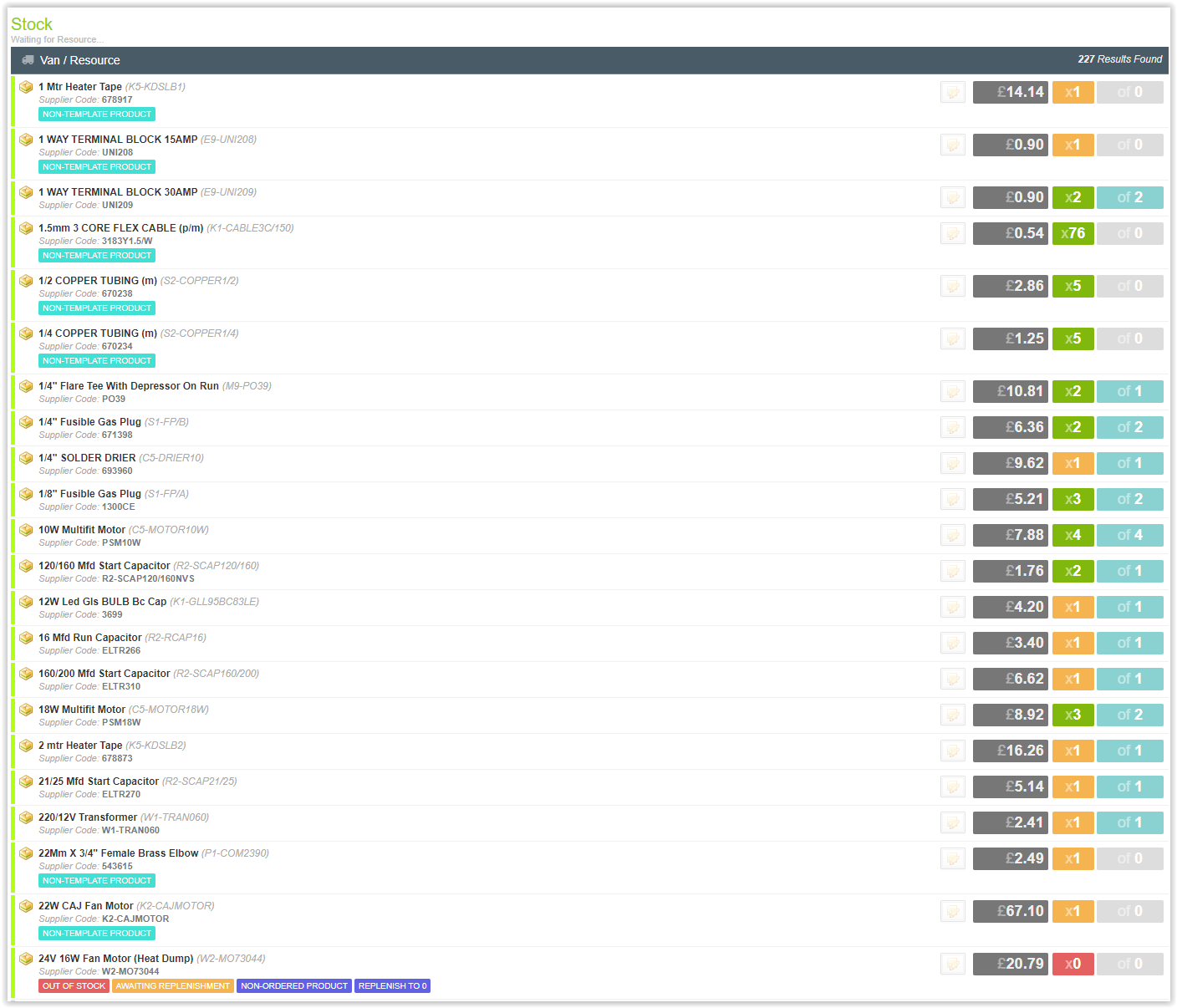

Advanced inventory management

Full control of parts purchasing and traceability of stock

- Real-time visibility of van, warehouse, reserved and site stock

- Audit trail of stock ordered, collected, consumed and returned

- Complete stock and inventory audit trail

- Automated supplier price and availability checks

- Rolling stock management process

Automate van stock replenishment

Van stock templates control what parts field maintenance engineers hold on their vans. These are driven by asset profile and the nature of your contracts, making it easy to adjust the number and combination of parts needed. You can also automate van stock replenishment orders to your main suppliers, improving engineer efficiency and first-time fix-rates.

The Aeromark support team always send really clear and concise emails around testing and changes to the system.

They're also very patient on calls when some of the questions we're asking may sometimes be unrealistic.

Customer Feedback Survey, 2024

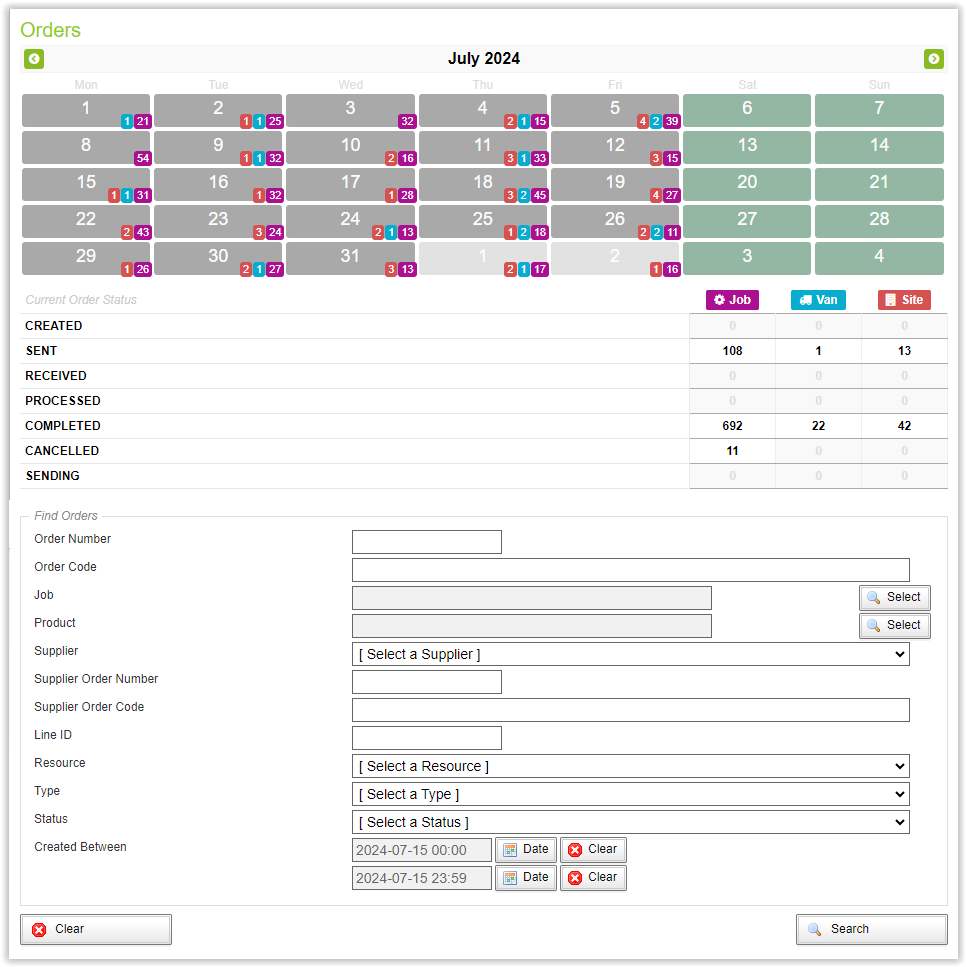

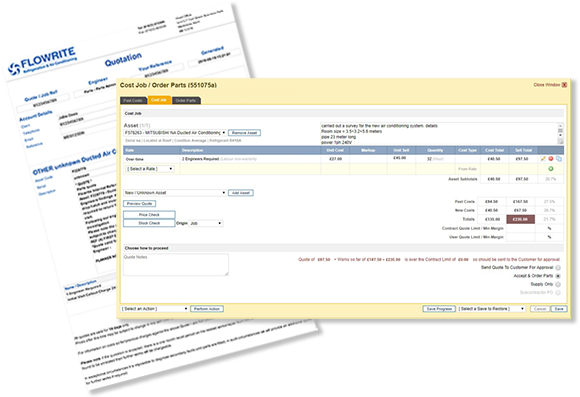

Automate tasks for increased efficiency and lower costs

Eliminate all your service-related paperwork with seamless automated processes for:

- Surveys

- Work management

- Bill of materials

- Quotations

- Purchase orders

- Compliance documents

- Invoicing

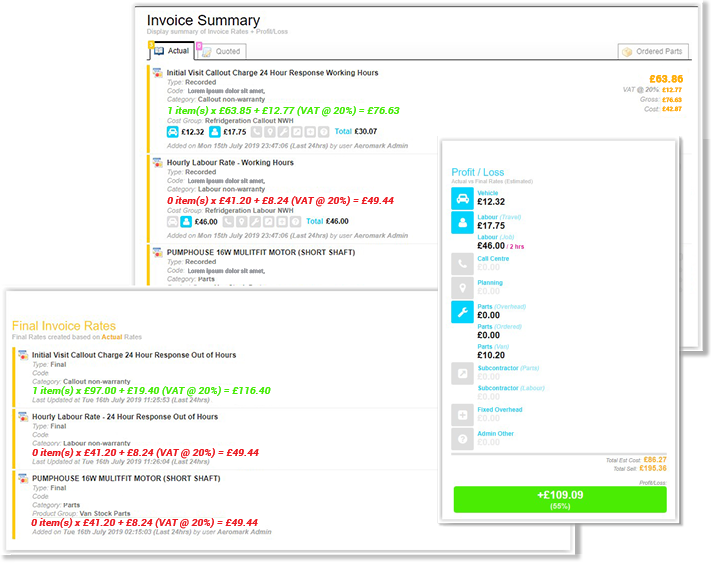

Take control of profit

Invoice data can be automatically applied throughout a job’s progress such as parts used, additional resources deployed, labour rates and margin. Aeromark’s Automatic Rating feature applies engineers rates and checks that parts ordered for the job have been consumed and the correct costs have been applied. This minimises errors and provides the visibility to see whether margin, and therefore profit, is being maintained or eroded.

Crucially, these controls, combined with a comprehensive data audit trail, enable you to analyse and identify which jobs and what type of work is the most profitable.

Ready to Start your Digital Transformation Journey?

If you are an enterprise service business with a significant number of service engineers or subcontractors, or you have complex requirements that an 'off the shelf' product cannot solve, we have the perfect solution for you.

Contact our team to discuss your requirements and arrange a product demonstration to discover how Aeromark’s Service Management software can benefit your business.

%20(1).webp?width=692&height=118&name=metcor_logo.png_resized_696_%20(2)%20(1).webp)