Choosing a complete business solution to run your service business can be fraught with risk, professionally and financially. The difficulty in choosing the right software solution often comes from a lack of visibility across the business which makes identifying all the problems the system could resolve challenging.

Often important considerations get overlooked as a single problem that needs urgent attention forces a tactical decision. Eventually, however, this can create additional silos in your service delivery or simply pass the problem from one department to the next.

In this guide we cover all the key aspects of a complete business solution and the benefits of working with a true Digital Transformation Partner to help you get the best from the system.

Digital transformation is a strategy not a tactic.

Efficient Automation with Field Service Management Software

Efficient automation that offers seamless dynamic workflows, eliminates manual tasks, and increases the productivity of your service team is vital when looking for your business solution, it is possible that you are already adequately resourced but not using your engineers’ or back-office staffs time effectively.

Recruiting and retaining field service engineers is an ongoing challenge across the service industry so the right system enables you to recruit time and not people.

This is equally true for the back-office and administrative staff where automation increases accuracy and frees people for more fulfilling and creative tasks.

A good solution should offer you end to end visibility of all assets, servicing, contracts, warranties, inventory, price books, costs, labour rates, margin, and invoicing in one centralised business-wide platform.

A complete business solution goes further by enabling you to increase your asset uptime with automated preventative maintenance (PPM). The system automatically schedules PPM jobs to flag alongside any reactive tasks scheduled with existing customers, without affecting your customer service level agreement (SLA) or customer experience (CX), minimising driving time and maximising tool-time.

Optimised Workforce Scheduling Software

When choosing a system make sure it offers resource scheduling and optimisation tools that gives you the power to see your resources clearly, unlock new levels of productivity, and deliver the best customer experience.

The Aeromark offers multiple scheduling options combined with GPS tracking to create the most efficient job schedules and routes.

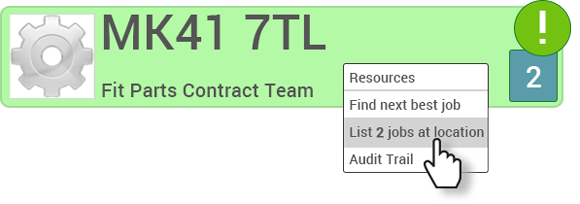

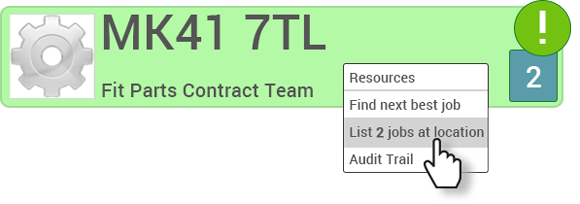

When reactive callouts are received, multi-intervention dynamic scheduling identifies other planned and reactive maintenance work at or near the location so engineers can complete them at the same time. This cuts out multiple callouts to the same location meaning engineer’s time is used more efficiently and fuel consumption and CO2 emissions reduced.

To ensure customer satisfaction Aeromark goes even further with the introduction of “promise time” which ensures that once a promise of attendance has been made to a customer it should be adhered to within any schedule.

Mobile Field Service Management

A complete business solution will not only optimise back-office processes but also empower field service engineers to be more self-sufficient on call outs.

Choosing a system with an integrated mobile app for both field service engineers and subcontractors will increase your first-time fix rate and reduce calls to and from the office so your back-office team can focus on other tasks.

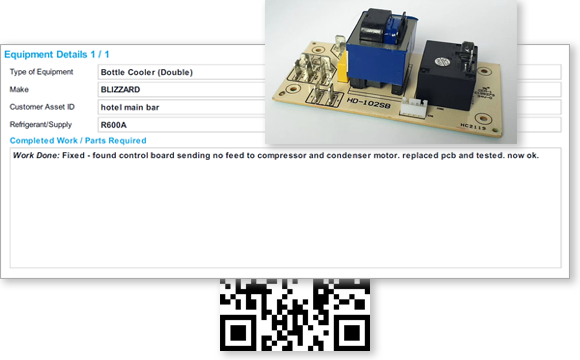

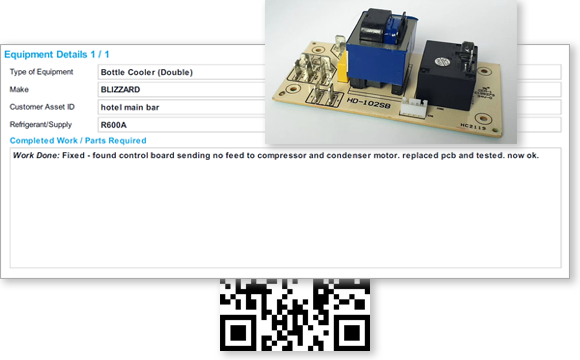

The mobile app can automatically create job sheets, compliance certification, quotes, capture photographic evidence, log the time spent on site, parts used, rates applicable to the customer and a customer signature on job completion.

The Aeromark complete business solution also enables engineers to compile comprehensive surveys of a job quickly and easily. This will then automatically produce a bill of materials and automatically price-check parts at the correct rate according to the customer's SLA.

Engineers can compile a photographic record of key property information such as location of equipment and any issues on site. This forms part of the installation record and audit trail to provide a full understanding of what is needed so that an accurate quotation can be given to the customer. Once the customer accepts the quotation, a fixing list, and Bill of Materials (BOM) can be automatically raised on the system.

GPS Tracking for Field Service Management

Aeromark were the first in the UK to develop and commercialise GPS tracking. Many service businesses already use this technology to track their fleet. However, a complete business solution should give you far more information than just the location of your vehicles.

Aeromark Tracking system or tracking within the Aeromark app is integrated with the Service Management platform. By pairing GPS data with the relevant customer’s SLA, details of the job needed - including the skill set needed to complete it, ensures the most efficient allocation of your field service engineers and the best customer experience.

Optimised route and schedule planning reduces overall service costs and increases productivity, enabling your engineers to complete more jobs, on the first visit, per day. Better scheduling can deliver more jobs per day, but it is only when integrated with Parts Management that we get more completed jobs per day; and that is where the secret to service profit lays.

Parts Management and Inventory Stock Management

Effective parts management sits at the heart of any efficient field service operation because managing your supply chain is as important as managing your engineers. Eliminating manual processes reduces human error and operational issues and reduces costs in your supply chain.

In the ever more competitive service management market, improving first-time fix rates (FTFRs) require full visibility of the spare parts stock and value carried across the business at any time so field service engineers can be correctly and efficiently deployed.

A complete business solution offers automated processes for the management of inventory, orders, dispatch, tracking, parts replenishment, and parts returns that will deliver productivity and cost saving benefits.

Aeromark system offers automated vehicle stock templates to control which parts engineers need onboard to complete the jobs. As stock is used, the van stock replenishment system automatically sends orders to your supplier to replenish stock.