Eliminating inefficiency and reducing part management costs is key to maximising service profit. After all, service profits are driven by completed jobs and that often requires effective parts management to ensure your engineers can deliver first time fix, or, at worst, second time fix and a consistent number of jobs per day.

Parts management is a balancing act. If you understock, you impact engineer efficiency and first-time fix-rates, but overstock and you tie up valuable cashflow in parts.

Creating standardized processes for parts ordering and tracking is essential in minimizing back-office administration and saving field service engineer's time.

If you are relying on manual processes and spreadsheets for ordering, tracking, returning and replenishing stock, it is very likely you are also eroding your service levels and profit margins, may be without realizing it.

How to solve the challenges of critical parts management

To gain maximum cost and efficiency benefits, deploy a field service management system to manage all service functions from the work queues to parts management to invoicing.

This system should manage the scheduling of planned, and reactive maintenance and have the capability to work with IoT modules for preventative maintenance alongside getting the right parts, to the right engineer, at the right-time, as a joined-up, seamless process.

If you do not have a digital system for service management, or your current system is hindering your growth, it’s about time you invested in a cloud-based end to end digital transformation platform to improve efficiency and, crucially, to gain more visibility and control of your operations.

1. Implement dynamic workflows to manage your parts process

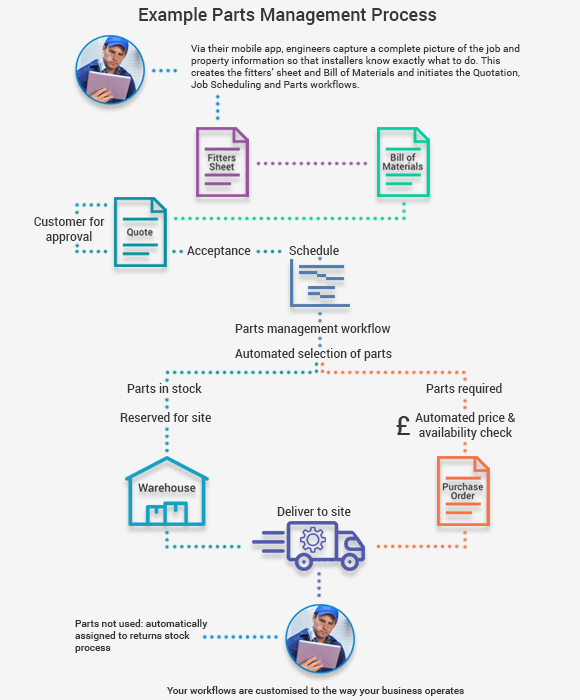

When a new job comes in, the service management system will digitally move jobs requiring parts to purchasing where automated processes for price checks, availability checks and purchase orders are then initiated.

If the parts are already in stock, the system can reserve them for a site, manage dispatch and notify engineers.

On receipt of parts, the job then moves to a dynamic scheduling workflow where the system will select the best engineer for the job based on multiple criteria including expertise, availability and location as well as the SLA and the time to arrive promised to the customer.

Automating the process of ordering, tracking and reserving parts for customer jobs provides full traceability of parts ordered, collected, used on site and returned, including the quantity and value of stock held in your warehouse, reserved for site and engineer’s vans.

Stock loss is minimized. Administration is dramatically reduced. First-time fix-rates increase. Your parts ordering process is now standardized, efficient and trackable, at every stage.

2. Automate van stock replenishment

When an engineer arrives onsite to a reactive maintenance call but lacks the spare parts in their van to fix the job first time, what do they do?

- Do they drive to the nearest retailer, purchase the part and return to site to complete the job?

- Do they leave the customer with a broken asset while the back-office team order the part, get it delivered and rebook the job?

- Do they call another engineer and transfer the part from their van stock?

None of these scenarios are ideal, and make spare parts challenging to track, cost and audit. But there is another way.

Stocking vehicles with spare parts for minor fixes can significantly reduce downtime and related costs, leading to happy customers and more profitable service calls.

A service management system can transform your maintenance and repair operation by managing and tracking van stock more efficiently.

Via their smart phones engineers can check parts out of their van stock, which triggers an automated replenishment order when van stock reaches a minimum level, which keeps stock levels down and increases first-time fix-rates.

Digital stock templates can control what parts your vans should hold. These can be driven by location and the nature of specific customer contracts and make it easy to adjust the number and combination of parts required at any time.

3. Automate price and parts availability checks

When supplier price books are held within your field service system, automatic spare parts price checks can be carried out, initiating a quotation, purchase order and invoice.

This ensures your workforce is ordering and billing the right parts at the right price, cuts down on paperwork and increase invoicing accuracy.

The system retains the approved mark-ups for each contract, so the quoted rate is always right.

4. Improve quote and purchase order efficiency in the field

Empowering your engineers with a mobile engineer app reduces mundane back-office administration and removes any delays in raising purchase orders and receiving parts.

Engineers onsite can compile a comprehensive digital survey of the job which produces a bill of materials and quotation, including automated price checks for parts, labour rates and any additional resources required.

This information triggers an accurate, automated price checked quotation which is emailed to the customer and when accepted, a service request is seamlessly raised on the service management system for parts ordering and scheduling.

5. Avoid failures through human error

By removing manual processes from your parts management, you reduce the risk of human error that creates operational issues and increases costs in your supply chain.

With a digital platform, stock levels, orders, dispatch, replenishment and stock for return is managed with simplicity.

Summary

Field Service Management has evolved. Digital transformation is no longer a nice to have, but a necessity. To optimise your critical spare parts management, you need to embrace the change and:

- Implement digital workflows to manage your parts process

- Automate van stock replenishment

- Automate price and parts availability checks

- Improve quote and purchase order efficiency in the field

- Avoid failures through human error

It’s about time you spoke to Aeromark about your digital transformation journey.