Field service delivery has become increasingly complex over recent years. Supply chain disruptions, staffing shortages and a growing emphasis on Environmental, Social, and Governance (ESG) are just a few of the challenges that make managing field services so demanding.

Adding to this are technology disruptions, market shifts, new competitors, rising customer expectations, and execution challenges.

The crux of the problem is that many traditional field services systems fail to measure and drive real value; and you cannot deliver the best quality of service and customer experience if your field service engineers, planners and back-office teams are bogged down by inefficient systems, manual processes and a lack of visibility.

However, by leveraging digital technology with a strategic single platform rather than multiple tactical applications you can achieve connected and autonomous experiences, proactively addressing needs in any area.

Do you need a new Field Service Management System?

The first step is to identify if there are any potential areas for improvement throughout the entire customer journey. As they say, if it ain't broke, don't fix it!

Take a helicopter view of your business and answer the following questions:

- What are your most profitable jobs?

- Do you know the exact location of all parts, and their value at each location?

- Do you have real-time control and visibility of your engineers’ schedules and their performance?

- Do you have complete visibility of the stock carried in each engineer’s vehicle?

- Are you confident that parts are fully accounted for and never go missing?

- Do you have automated processes for replenishing van stock, or returning parts that haven’t been used on a job?

- How quickly do you turn around quotes; within 2, 24, 48 hours? Could speeding up the process help you win more business?

- Given the daily cost of your engineers, vans, and back-office processes, is your job scheduling and number of completed jobs giving you the best return on investment?

- Is it easy to create reports on contract profitability?

- How many people and spreadsheets are involved in managing your operations?

If the answers to these questions doesn’t come easily, it’s about time you invested in a cloud-based end to end digital transformation platform to improve efficiency and, crucially, to gain more visibility and control of your operations.

Here is our 10-step strategic plan to improving your field service profit

Follow this guide to create a strategic plan for positive change for your service management business. You will reap the benefits of:

- increased customer acquisition and retention

- improved margin on service and maintenance jobs

- increased productivity and profit

Contents

- Tackle field service engineer productivity first

- Remove unnecessary touchpoints in your processes

-

Empower your field service engineers to achieve first time fix

.png?width=600&height=400&name=Untitled%20design%20(26).png) 1. Tackle field service engineer productivity first

1. Tackle field service engineer productivity first

Conduct a thorough review of your processes from your customers’ first engagement with your service desk to successful completion of the job, and final invoicing.

- Could your first-time, fix-rate be improved?

- Are your engineers making multiple visits to the same site for jobs that could easily be scheduled together; such as carrying out planned maintenance work when responding to reactive calls?

- Follow a job from first call to final invoice – how many touchpoints are there?

By implementing Dynamic Workforce Scheduling you gain unparalleled visibility and control and helps you achieve higher first-time fix rates and revenue per field service engineer, while also eliminating mundane back-office processes.

Look for a solution that offers multiple scheduling options, combined with GPS vehicle or device tracking, service level, contract and skills data to create the most efficient job schedules and routes for your engineers.![]()

2. Remove unnecessary touchpoints in your processes

2. Remove unnecessary touchpoints in your processes

Follow a job from start to finish and identify all the steps in your processes where efficiency improvements can be made in:

- scheduling

- route planning

- parts ordering

- inventory management

- van stock management

- communicating with engineers

- invoicing

Make a note of how many tasks are done manually, and/ or managed in silos via spreadsheets and emails.

And how many issues could be solved by joining up disconnected processes, so that work flows seamlessly and automatically from one task, and function, to another?

Aeromark offers one end to end platform to optimise your operational efficiency, minimise touchpoints and reduce administration. Nine powerful modules create a single, seamless cloud-based platform providing agility, visibility and control of your entire service business. Each can be deployed in a phased approach to optimise specific operations.![]()

3. Empower your field service engineers to achieve first time fix

3. Empower your field service engineers to achieve first time fix

Are your field service engineers equipped with all the necessary information to achieve a first-time fix? If you want to be more profitable, it's crucial to dispatch the right service engineer who has:

- all the required site and asset information,

- the right training and qualifications,

- the right parts in their van stock to complete the job, and

- knows the customer is available and expecting them.

While this may seem straightforward, it is often more challenging than it appears.

With an end-to-end service management system, the engineer’s job schedule is clearly laid out with full details including relevant site and asset information, service history and asset specifications via their smart phones, making the engineer experience as simple as possible.

Automated real-time SMS or email notifications keep customers informed about their service appointment and engineer location and allows them to easily rearrange when more convenient for them reducing “not at homes.” ![]()

4. Combine reactive maintenance and planned maintenance jobs

A common scenario when you do not have joined up systems is an engineer can be called out on a reactive maintenance job one week, only to return to the same site a week later for a routine visit. Combining planned maintenance and reactive maintenance service calls like this will significantly increase the overall productivity of your team.

A common scenario when you do not have joined up systems is an engineer can be called out on a reactive maintenance job one week, only to return to the same site a week later for a routine visit. Combining planned maintenance and reactive maintenance service calls like this will significantly increase the overall productivity of your team.

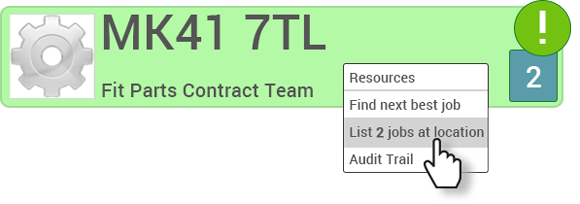

When reactive callouts are received a multi-intervention feature in your service management system will automatically flags other planned maintenance or reactive work orders, at or near the same location which can be done at the same time.

Furthermore, dynamic route planning cuts down mileage, journey time, reduces fuel use (remember those ESG pressures) and allows more jobs to be completed per day.![]()

5. Digitise your service management job cycle

Manually creating all the paperwork required for surveys, quote and stock replenishment takes time, is mundane and repetitive and is prone to human error.

Look for ways to streamline your service requests from issue detection to resolution, and invest in a digital system that enables engineers to:

- Automatically created job sheets and quotes including photo capture, time on site, parts used, rates and customer signature.

- Initiate inventory orders via their mobile device.

- Complete compliance certification generated automatically once the engineer has completed the job.

- Eliminate all service-related paperwork, meaning engineers can move on to the next job in their schedule without getting tied up in admin.

Implementing automated workflows enable staff and subcontractors to manage and complete jobs more efficiently, including job surveys, parts purchasing, quotations, van stock replenishment, commercial sign-off and invoicing.

Quotations can be generated immediately, which means customers approve them faster and that increases the number of jobs you do.

Urgent business critical quotes are prioritized to provide a quicker response. Invoices can be generated as soon as your engineer completes the job.![]()

6. Ensure invoicing is speedy and accurate

6. Ensure invoicing is speedy and accurate

Accurate invoicing is arguably the most crucial cog of the back-office machine. After all, how else will you collect your company’s hard-earned cash?

Unpaid invoices are far more costly than you might realise. Chasing debts and recovering fees diverts resources that could be utilised for more productive activities.

With a service management platform, invoice data can be automatically tracked throughout a jobs progress such as parts used, additional resources deployed, labour rates and margin. Invoicing is quicker and, most importantly, accurate which in turn improves cash flow.

Aeromark service management system goes one step further and has an automatic rating feature which checks that parts ordered for the job have been used and the correct margin and rates have been applied.![]()

7. Manage inventory more effectively

7. Manage inventory more effectively

Effective parts management sits at the heart of an efficient field service operation. Eliminating manual processes reduces human error, operational issues and costs in your supply chain.

With a digital platform, stock levels, orders, despatch, replenishment and stock for return is managed with simplicity.

Parts management is at its most efficient when quotations, parts purchasing, job scheduling and billing are managed by a seamless joined up workflow; with automated processes for ordering, reserving, despatching and tracking stock for customer jobs.

Aeromark field service management system offers automated vehicle stock templates to control which parts engineers need onboard to complete the jobs assigned to them. As stock is used, the van stock replenishment system automatically sends orders to your supplier to replenish stock.![]()

8. Gain visibility of your van stock

8. Gain visibility of your van stock

Even if you have a good parts management system in place, having complete visibility of the stock carried in each engineer’s vehicle is often harder to achieve.

Mobile workforce efficiency and first-time fix-rates are severely impacted when engineers don’t have the right parts in their vans.

A service management system can transform your maintenance and repair operation by managing and tracking van stock more efficiently including automatic parts replenishment to your main suppliers.

Van stock templates control what parts engineers hold on their vans. These are driven by asset profile and the nature of your contracts, making it easy to adjust the number and combination of parts needed. You can also automate van stock replenishment orders to your main suppliers, improving engineer efficiency and first-time fix-rates.

Giving engineers access to your service management system in the field through workflow driven mobile apps reduces back-office administration, delays in raising purchase orders and receiving parts.![]()

9. Know when service contracts are reaching margin thresholds

9. Know when service contracts are reaching margin thresholds

We have already established it is essential to control and monitor your profit margin. But this is not as easy to achieve when you are working from multiple spreadsheets, multiple systems or relying on mundane manual processes.

Choose a system that captures costs and automatically applies the correct margin to your jobs. This minimises errors and provides the visibility to see whether margin, and therefore profit, is being maintained or eroded.

Crucially, these controls combined with the data audit trail enable you to analyse, understand and which jobs and what type of work is the most profitable, and therefore make key strategic decisions about how you can grow profit.![]()

10. Improve your reporting & analysis capability

10. Improve your reporting & analysis capability

Your data is one of your most valuable business assets. You need to understand the costs, productivity and profitability of your jobs, pinpoint dips in performance, and identify root causes to be a strong, robust business.

Real-time visualised data, key performance indicators and metrics should be quickly and easily available, in dashboards an automated report, to gain the visibility needed to understand overall performance.

Choose a digital transformation partner who will work with you to implement effective dashboards and reporting at all levels of your business, ensuring your leadership team and managers can make effective decisions and drill down to specific areas of compliance.![]()

In summary, our advice for a strategic growth plan is:

- Tackle poor productivity

- Eliminate touchpoints that don’t add value

- Empower your engineers with automated tasks to increase performance

- Optimise scheduling of reactive and planned maintenance

- Speed up your service cycle

- Make invoicing speedy and accurate

- Manage inventory more effectively

- Control the management of van stock

- Know if your jobs are profitable

- Get full visibility of your data

If you need help in any of these areas, then it’s about time you spoke to Aeromark about digitally transforming your service delivery.